Our Systems

MaxilodaGlide

Developed from the challenge of improving the efficiency of the transport fleet supply chain by improving the flexibility, utilisation, efficient use of labour, while also improving the customer experience. To enable improved utilisation a second level (double stacking) was a logical approach and the Maxiloda Glide Metro was born.

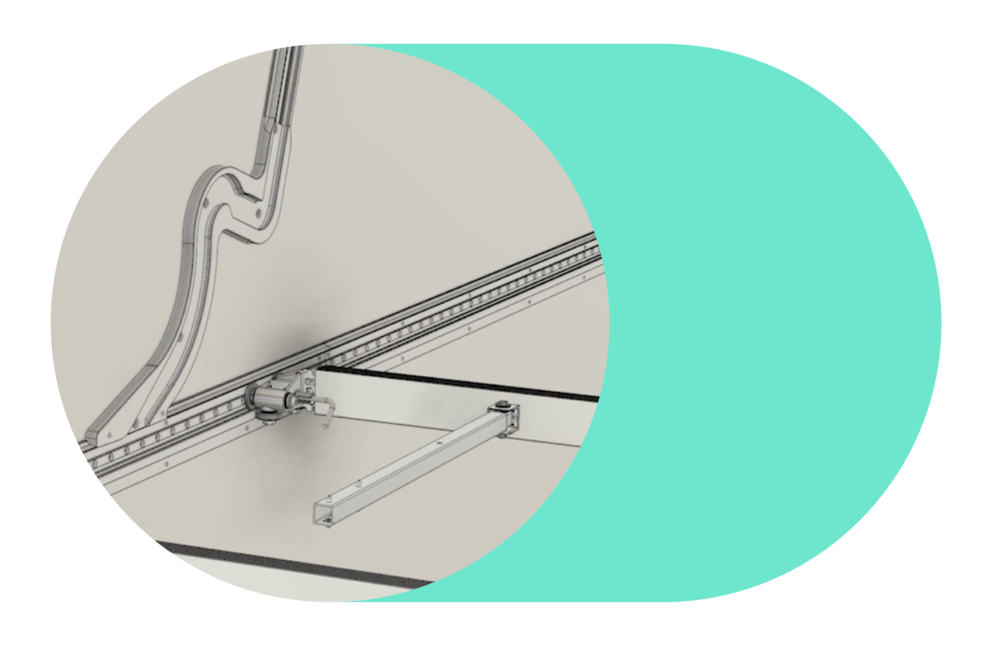

The maxiloda glide system

Developed from the challenge of improving the efficiency of the transport fleet supply chain by improving the flexibility, utilisation, efficient use of labour, while also improving the customer experience. To enable improved utilisation a second level (double stacking) was a logical approach and the Maxiloda Glide was born.

Whilst there are other stacking

products on the market

their current stacking models the second level being stacked directly on top of the product below on static beams. This requires a forklift of some type to enter the trailer to complete the loading or unloading of the goods. To enable a forklift to enter a trailer a dock way is required to enable the loading and unload of the trailer.

The Maxiloda Glide moves product via a rolling trolley on the second level to the back of the trailer, no forklift is required to enter the trailer, you achieve flexibility of load configuration, quick turn around of load, elimination of damages.

The key difference however is no dock way is required and goods can be loaded and unloaded in the double stacked configuration, maximising time and load. Customers now have flexibility of delivering direct to where the product is required, not necessarily through a DC Hub.

Double stacking storage solutions

for trucks and trailers

Vans/Metro

Trucks/Light

Trailers/HGV

Maxiloda Lift

A clear advantage of the Maxiloda Glide solution is the ability to load and unload a double stacked trailer from the rear without a dock-way. With significant numbers of Glide installations under their belt, the Maxiloda team could see there was an additional efficiency gain to be had by having a trailer fitted loading and unloading system – The Maxiloda Lift the first of its kind, was created to do just this.

Currently there is no product on the market that is integrated on a trailer that enables the loading and unloading of a double stacked system. All current loading and unloading is achieved via a dock-way with a forklift. This requires both a dock-way and a forklift to be available as well as a certified forklift operator to complete the loading and unloading process. This equals investment, time and safety concerns for the end customer.

The Maxiloda Lift is an integrated device that loads and unloads the trailer from the rear deck as well as the second level. The Lift system and the lift operator does not need to be specifically certified for the use of the system. The trailer load can be managed independently from the overall supply chain coordination as the transfer process – truck, trailer loading and unloading is an independent unit. The Maxiloda Lift also allows intermediate drop offs, between DC’s to smaller retailers and suppliers, as well as the back-haul utilisation of loading of goods in route between DC’s.

Accessories

Copy TBC

Customised Solutions

Copy TBC

Case studies

Book a free consultation

Innovative stacking and space optimisation systems for freight forwarders.